Choosing Stone paper leaves trees in the ground – where they belong – capturing C02 and reducing greenhouse gases, a critical weapon in the fight against climate change.

Stone paper and the Environment

| Environmental Impact | Pulp paper | Stone paper |

|---|---|---|

| Trees Consumed (per ton) | 20 | 0 |

| Water Consumed (per ton) | 16,000 Gallons | 0 |

| Energy Consumed | 19.3 Million BTUs | 3 Million BTUs (~84% less) |

| C02 Emissions | 3,300 Pounds | 1,322 Pounds (~60% less) |

| Hazardous Chemicals | Yes | None |

| Bleaches Required | Yes | None |

| Dyes Required | Yes | None |

| Creates Air Pollution | Yes | None |

| Creates Water Pollution | Yes | None |

| Results in Deforestation | Yes | None |

Is Stone paper the cleanest paper ever produced?

Stone paper products require no bleaches, acids, alkali, or other potentially dangerous ingredients to achieve its white color. Instead, our exceptionally white paper is derived from the high concentration of naturally white CaCO3 mineral content. As a result, the manufacturing of our Stone paper materials produces no pollution to the air, rivers and waterways with any harmful chemicals.

Stone paper vs. Pulp Paper

Why choose Stone paper products?

- Utilization of minerals, CaCO3 vs. pulp fiber and freshwater

- Manufacturing requires far less energy, resulting in much lower CO2 emissions

- No waterways are polluted with toxic effluent

- Stone paper = No trees, no water, no dyes or bleaches

Sustainable, waterproof, tear-resistant paper with endless applications.

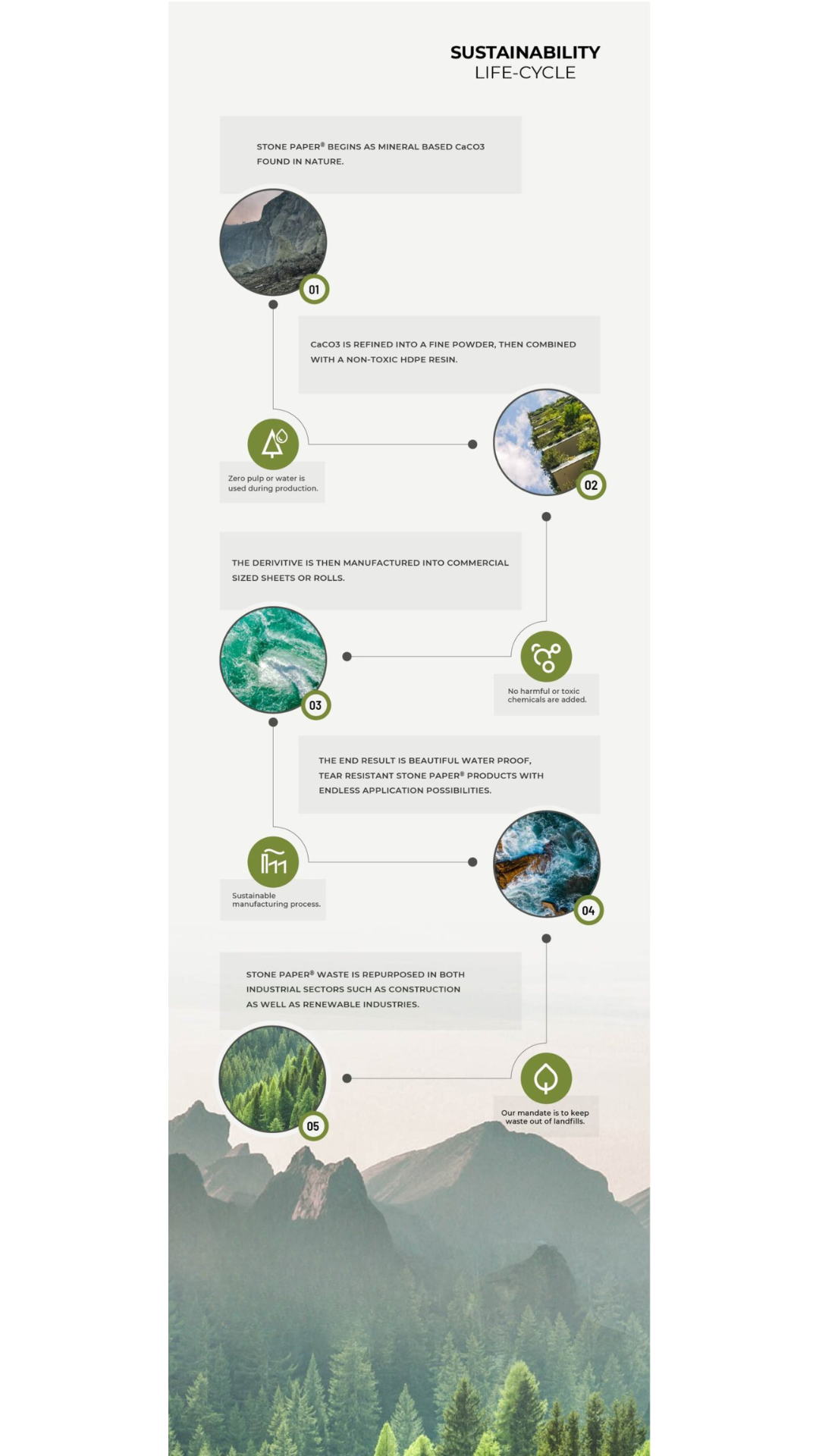

The Stone paper Lifecycle

Stone paper products prove to be nature’s promised future. Making paper out of minerals helps preserve the environment and save the planet for our future generations.

CO2 Footprint

Up to 67% smaller than paper made from other materials.

By eliminating pulp fiber from our production process, Stone paper is not only counteracting the creation or increase of any greenhouse gases, but its mineral paper manufacturing process contributes significantly to the reduction of carbon footprint.

Stone paper products carbon footprint is further reduced because its manufacturing process uses approximately half the energy of comparable material production.

Stone paper manufacturing process uses only electricity during production contributing even further to our environmental responsibility.

Stone paper contributes to rainforest protection

While many believe printing and the use of paper is a dying industry, consumption of paper has actually risen by 400% in the past 40 years.

Stone paper believes in playing its part. We believe this innovative product helps offsetting climate change, desertification, soil erosion, crop reduction, flooding, increased greenhouse gases in the atmosphere, and a host of other problems for indigenous people.

Re-purposing by Stone paper

With industry-leading durability, we encourage our clients to find new ways to reuse their finished products. Excellent examples of such reuse can be found at the Summit at Snoqualmie and Squaw Valley Alpine Meadows, where resort guests have the opportunity to return Stone paper ski trail maps at the end of the day for others to use.

We can currently recycle Stone paper waste back into mineral paper at our main facility overseas and estimate opening a mill here in the next 3-5 years to provide for production and recycling in North America. We’re currently working on developing a new repurposing facility whereby new innovative products can be developed. So far we’ve worked on products such as wallboard and composite decking. We ask clients to contact us for any interest in bulk Stone paper product repurposing.